Air pollution in buildings will negatively impact occupant health and wellness. Is your building sick? This hidden issue is increasingly being exposed; no one really knows whether the air they are breathing is toxic.

The rising interest in IAQ correlates to rising concerns about health and wellness in the built environment. Concerned companies have already taken active steps to target healthier and more productive interior spaces. The mere notion of living or working in a space filled with airborne pollutants is rapidly becoming a non-starter.

The industry problem, of course, is that no one really knows what the pollutant levels are at any given time within the interior space. The Internet of Things (IoT) industry has rapidly advanced IAQ applications because traditional building infrastructures such as a Building Automation System (BAS) or Energy Monitoring System (EMS) weren’t necessarily designed to protect the most important “assets,” building occupants.

New IAQ sensor applications continue to emerge. This guide provides a survey of a current set of IAQ use cases that you should be aware of going forward.

Carbon Dioxide (CO2)

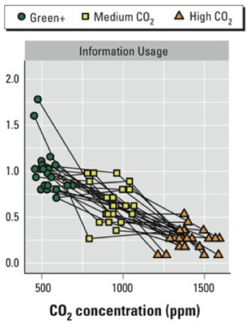

Historically, CO2 represents the most familiar IAQ metric known to the HVAC industry. A study published in Environmental Health Perspectives found cognitive functions suffered when exposed to elevated CO2 levels. We didn’t need a study to tell us that when conference room conditions feel “stuffy” then concentration levels suffer.

Historically, CO2 represents the most familiar IAQ metric known to the HVAC industry. A study published in Environmental Health Perspectives found cognitive functions suffered when exposed to elevated CO2 levels. We didn’t need a study to tell us that when conference room conditions feel “stuffy” then concentration levels suffer.

California’s Division of Occupational Safety and Health Policy and Procedure Manual (P&P No. C-48) specifies that CO2 concentration levels should be measured when occupants report “stuffy” conditions. In another example, the New Jersey IAQ Standard specifies in their compliance program that an employer shall designate a person to assure compliance to actions including, “[w]hen the carbon dioxide level exceeds 1,000 parts per million (ppm), the employer shall check to make sure the HVAC system is operating as it should.”

It has been well established that cognitive functions improve with better ventilation control that addresses high CO2 levels. Interest in active measurement of CO2 levels is increasing because workforce improvements through real-time control of CO2 levels will accrue significantly to the bottom line.

Particulate Matter (PM)

The struggles with wildfires in California, and most recently in Australia, highlight the health risks of PM. A recent study examined the use of IoT sensing and occupant surveys for determining the resilience of buildings to forest fire generated particulate matter with 2.5 μm diameter PM (PM2.5). There is clear evidence that wildfire smoke, which includes PM2.5, is linked to respiratory health implications, morbidity, and mortality (See the related article here and another related article here). While wildfires represent extreme air pollution events, the HVAC industry is not designed to address PM concerns directly.

The struggles with wildfires in California, and most recently in Australia, highlight the health risks of PM. A recent study examined the use of IoT sensing and occupant surveys for determining the resilience of buildings to forest fire generated particulate matter with 2.5 μm diameter PM (PM2.5). There is clear evidence that wildfire smoke, which includes PM2.5, is linked to respiratory health implications, morbidity, and mortality (See the related article here and another related article here). While wildfires represent extreme air pollution events, the HVAC industry is not designed to address PM concerns directly.

The American Society of Heating Refrigerating and Air-Conditioning Engineers (ASHRAE) 62.1-2019: Ventilation for IAQ specifies its updated standards for ventilation system design and acceptable IAQ. Multiple methods are allowed to control common pollutants indoors to reduce the risk of health concerns in new and existing buildings.

Three procedures for ventilation design are specified, namely the IAQ Procedure, the Ventilation Rate Procedure, and the Natural Ventilation Procedure. Historically, the Ventilation Rate Procedure is the most commonly used method to control contaminant levels through airflow specifications. Significantly, real-time IAQ measurements are not required because it relies on proper ventilation to indirectly solve the pollution problem.

Air pollution events that implicate rising PM levels are not typically addressed in buildings today because active, real-time PM sensing barely features in even the most modern of built environment spaces. Increasing usage of PM sensors is expected, especially in those areas that are prone to extreme air pollution events such as wildfires.

Volatile Organic Compounds (VOCs)

VOCs represent organic chemicals (i.e., chemical compounds that contain carbon) that have a high vapor pressure at ordinary room temperature. This causes large number of molecules to evaporate from the liquid or solid form of the compound and enter the surrounding air. Concentrations of many VOCs are consistently higher indoors (up to ten times higher) than outdoors.

VOCs include many chemicals that may have short- and long-term adverse health effects. The large number of chemicals that can be characterized as VOCs initially lead to sensor measurements of the Total Amount of VOCs (TVOCs). TVOC measurements can be useful to diagnose the general existence of VOCs in the environment as a first step in understanding the existence of harmful VOCs in an environment.

Formaldehyde (CH2O)

Formaldehyde represents one of the many VOCs that can have harmful effects. The WELL building standard outlines a specific requirement for measurement of formaldehyde levels in the built environment. Formaldehyde is widespread and is one of the most abundant VOCs. Due to its low cost, formaldehyde is commonly used by the chemical manufacturing industry in various capacities.

Formaldehyde is a colorless and strong-smelling emission. Inhaling air contaminated by even low levels of formaldehyde can cause burning and watery eyes. As pollutant levels increase, it causes burning in the throat, nausea, fatigue and difficulty in breathing. High concentrations may be particular problematic for individuals with respiratory conditions such as asthma. Off-gassing from new building products and furniture can be particularly problematic.

Formaldehyde is a colorless and strong-smelling emission. Inhaling air contaminated by even low levels of formaldehyde can cause burning and watery eyes. As pollutant levels increase, it causes burning in the throat, nausea, fatigue and difficulty in breathing. High concentrations may be particular problematic for individuals with respiratory conditions such as asthma. Off-gassing from new building products and furniture can be particularly problematic.

Recent events have only highlighted the increasing risks of formaldehyde pollution in the built environment. Recent regulations passed by California that impose tough limits on formaldehyde emissions from composite wood panels only highlights the increasing regulatory risks the industry faces.

The requirement for measuring concentration levels of specific VOCs will inevitably rise in the future. Formaldehyde represents just a single example. In another example, areas that include overt exposure to gasoline, factory and vehicle emissions should likely test for other VOCs such as benzene.

Ozone (O3)

Ozone is an inorganic gas that is commonly known to act in the upper atmosphere as an ultraviolet ray filter. On the earth’s surface or within interior spaces, however, it is an air pollutant. Thus, ozone can be good or bad, depending on where it exists.

Ground-level ozone is typically created by chemical reactions between oxides of nitrogen (NOx) and VOCs, for example, when pollutants emitted by cars, power plants, industrial boilers, refineries, chemical plants, and other sources chemically react in the presence of sunlight.

Ground-level ozone is typically created by chemical reactions between oxides of nitrogen (NOx) and VOCs, for example, when pollutants emitted by cars, power plants, industrial boilers, refineries, chemical plants, and other sources chemically react in the presence of sunlight.

Ozone pollution can be harmful to health, especially on hot sunny days when ozone can reach unhealthy levels. People most at risk from breathing air containing ozone include people with asthma, children, and older adults.

Carbon Monoxide (CO)

Most homes have some familiarity with carbon monoxide, which can be produced by burning gasoline, wood, propane, charcoal or other fuel. Improperly ventilated appliances and engines, particularly, may allow carbon monoxide to accumulate to dangerous levels. Because it is a colorless, odorless, tasteless gas, the risks are serious.

Signs and symptoms of carbon monoxide poisoning can include headaches, weakness, dizziness, nausea, confusion, blurred vision, and loss of consciousness. The fact that dangerous carbon monoxide exposure can occur in industrial environments, commercial buildings, and schools makes the early detection of rising carbon monoxide levels due to inadequate ventilation particularly acute. Many homes feature carbon monoxide detectors; the usage of real-time carbon monoxide sensing in CRE is lacking.

Conclusion

IoT has incorporated all of these IAQ sensors and more to provide real-time monitoring of IAQ conditions in the built environment. New and better IAQ sensors will continue to enter the market as IAQ needs increasingly evolve. What remains true is that IAQ applications enabled by IoT will expand rapidly into the future due to the known health impact that air pollution causes.